Low-pressure or medium-pressure pneumatic transport using mixers is the continuous transportation over short distances and with a smaller output suitable e.g. for transportation of separated fly ash in small boiler plants.

Thanks to the rotary feeder, the separated material is dosed into the mixer where it is carried by air through the pipeline into the target container. Compressed air is generated by a fan or air compressor.

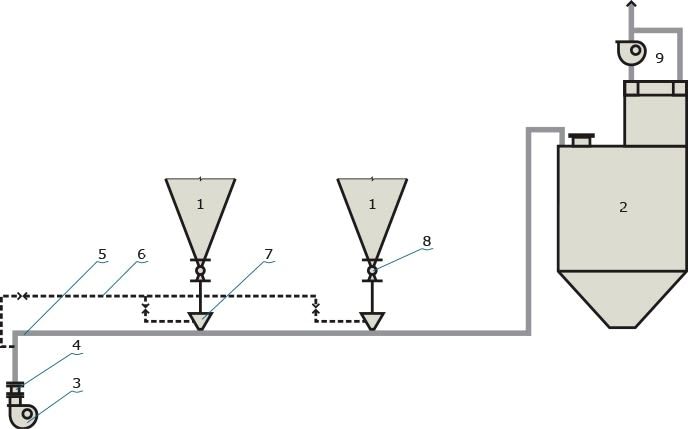

Example of equipment layout

- Separator hoppers

- Operating (storage) container

- Fan – source of transport air

- Dumping pad

- Pneumatic unloader

- Auxiliary air distribution, including the limiting orifice plate

- Material mixer

- Material feeder

- Hopper filtering equipment