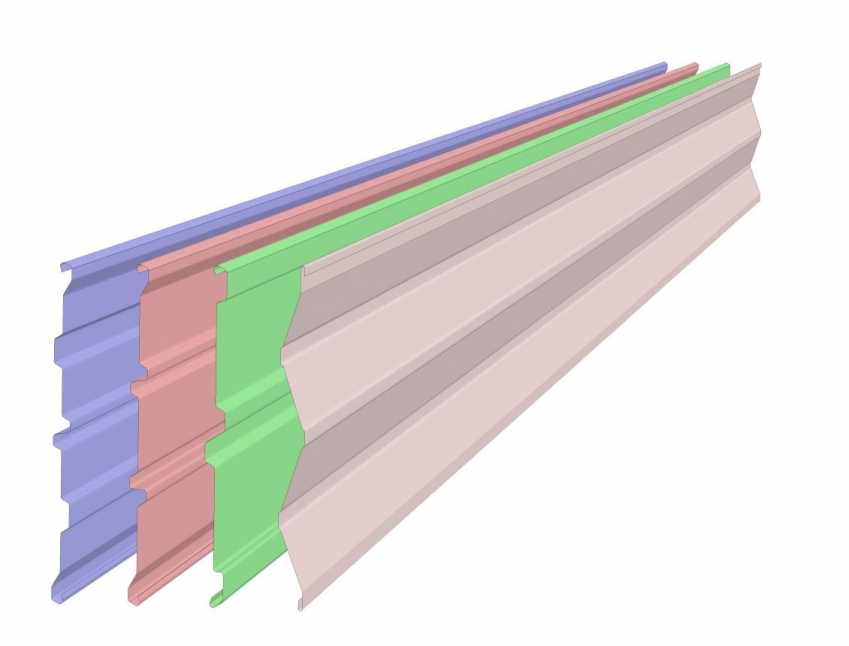

Passive electrodes are designed so that they are sufficiently rigid and also use, as much as possible, the envelope curves of corona discharges radiated from high voltage electrodes. They are manufactured by cold rolling from deep-drawn sheets with thickness between 1.2 and 1.5 mm

Types of profiles of passive electrodes

- V1 (width 640 mm) - EKO, EMO, EKK

- CS11 (width 640 mm) – EKH

- CS1 (width 640 mm) – EKG

- SCS (width 640 mm) – EKF

- CSH2 (width 480 mm) – EKE

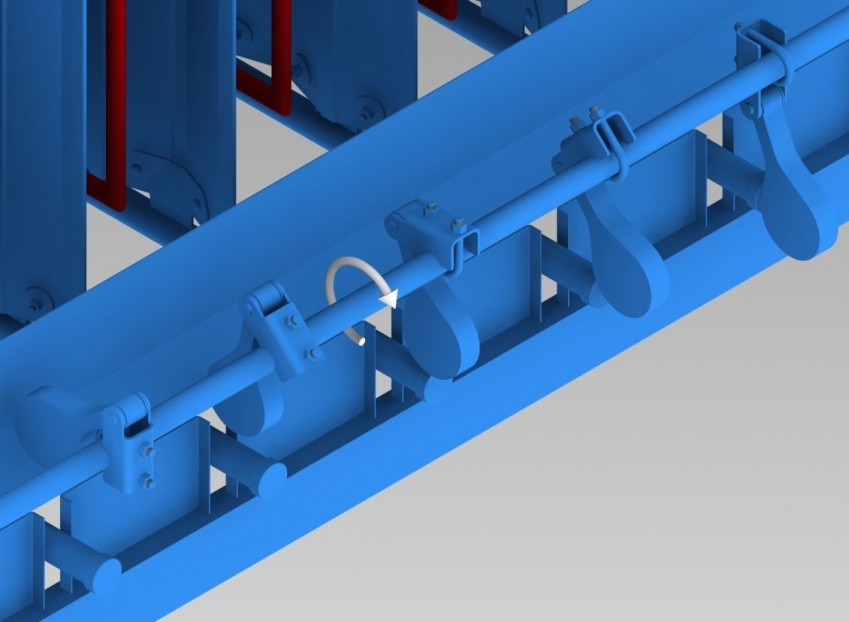

Suspension and rapping

Passive electrodes are attached, freely on pins, onto suspended beams. In the lower part, they are mutually interconnected in the rapping beam by preloaded rivet joints. The lower fixed attachment and upper free suspension guarantees a perfect transfer of energy from the rapping hammers to the entire line of passive electrodes.

The rapping is performed systematically in regular intervals and it ensures the removal of the settled dust from the electrodes into the hoppers.